Step 1

Mark out edge to be wired, with approx 8mm extra for making the wired edge. Use G104 Aviation Snips to cut to the 8mm line.

Step 2

Using Swage fit the jenny wheels to throw up an edge along the marked line (about 45 degrees).

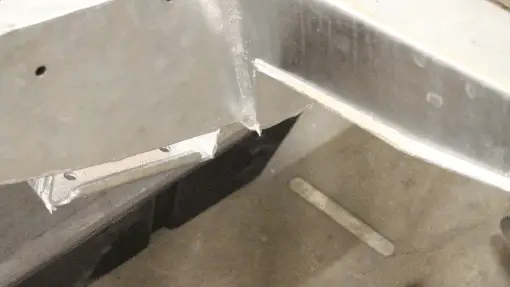

Step 3

Use the wiring wheels to form a U shape along the crease previously formed, the work piece will have to be tipped to so as to come down the face of the top wheel.

Step 4

Insert the wire in the U and trap it by using a hammer on the open edge at approx 150 mm intervals.

Step 5

Put the closing wheels on the machine and set the gauge approx 6mm behind the top wheel.

Step 6

Run along the length of the wired edge closing it sufficiently to securely trap the wire all the length.

Step 7

Set the closing wheel to one thickness of metal (about 1mm) and run down the edge again to give a full length, even finish